Understanding Spray Pressure, Flow Rate, Droplet Size and More

Understanding Spray Pressure, Flow Rate, Droplet Size and More

As a professional pest controller, you use your spray equipment day in and day out so it’s important to understand how different factors like spray pressure, flow rate, droplet size and coverage are all interrelated.

Adjusting one element can have significant effects on the others and overall influence the volume and uniformity of your pesticide application, as well as the risk of spray drift.

Why is spray pressure important?

Operating at the proper spray pressure is critical to maintain the correct spray droplet size, spray coverage, and flow rate.

Battery powered sprayers will automatically maintain a consistent pressure while manual sprayers require hand-pumping to maintain the pressure.

Tip: You can eliminate manual pumping from your B&G Primeline Sprayer by equipping the B&G Pressurising Tank Top (PTT) which replaces the traditional pump mechanism and automatically repressurises the tank to 30 psi when it drops below 23 psi. For those with Rega Spray Units, you can enjoy the benefits of the PTT with the Rega to B&G Adaptor.

What is the flow rate of a spray nozzle?

The flow rate refers to the output of the spray nozzle stated in gallons per minute (gpm) where 1 gpm = 3.785L/min.

The nominal flow rate of a spray nozzle is based on the volume sprayed by the nozzle when operated at a pressure of 40 PSI with water at 21ºC.

What are spray coverage and spray angle?

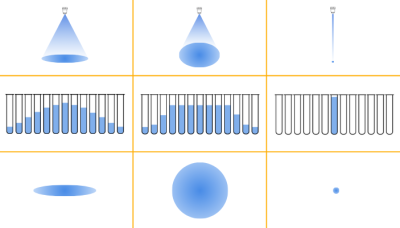

Spray coverage is the surface area that is covered by spray droplets during application. It is determined by factors such as the distance of the nozzle from the object and the angle of the spray as it exits the nozzle orifice.

Spray angle is usually measured in degrees, typically ranging from 0° to 80°. Generally, the wider the nozzle’s spray angle, the larger the coverage area.

What droplet size should I be using for pest control?

Droplet size is the diameter of the individual sprayed droplet measured in microns where 1 micron (μm) = 0.001mm. Droplet sizes range on a scale from extremely fine to ultra coarse.

As the droplets in each spray will not have a uniform size, the most accurate measurement is VMD (Volume Median Diameter). It divides the total spray volume into two equal parts, where half of the volume contains droplets smaller than the VMD, and half the droplets are larger than the VMD. The droplet size in the exact middle is the Volume Median Diameter.

For example for a spray that has a 300 micron diameter droplet size, this means that 50% of the spray volume is in droplets with diameters smaller than 300 microns, and 50% of the volume is in droplets that have diameters larger than 300 microns.

Tip: Read the label to understand what droplet size to use, for example fine or coarse. Droplet size is critical to some insecticide applications, especially fogging.

How are spray pressure, flow rate, droplet size and spray angle related?

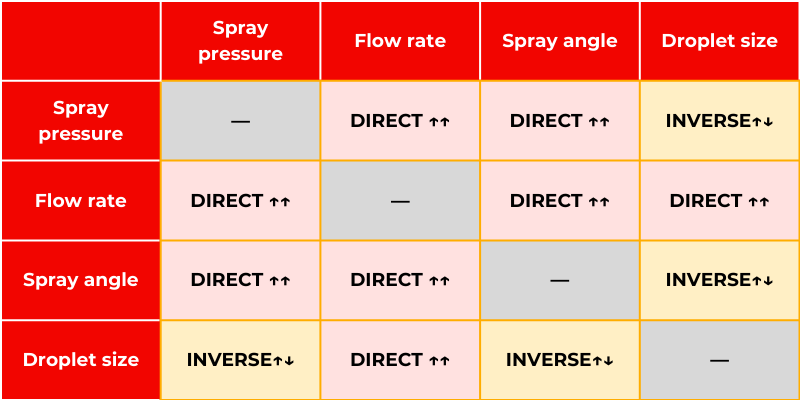

This summary table explains the relationship between these spray characteristics so you can understand how to adjust your spray settings to achieve your desired results.

- Spray Pressure ↔ Flow Rate – These are directly related so increasing the spray pressure will increase the flow rate. Meanwhile, decreasing the spray pressure will decrease the flow rate. It’s important to keep your application equipment operating at the proper pressure to ensure a consistent flow rate and therefore an even application of pesticide.

- Spray Pressure & Spray Angle ↔ Droplet Size – The inverse relationship means that increasing the spray pressure or spray angle will decrease the droplet size. Conversely, decreasing the spray pressure or spray angle will increase the droplet size.

- Flow Rate ↔ Droplet Size – These are directly related, so increasing the flow rate will increase the droplet size and vice versa.

- Spray Pressure ↔ Spray Angle – These are directly related to each other. Maintaining adequate spray pressure keeps the spray angle and coverage consistent. If you allow your spray pressure to decrease, this will in turn reduce the spray angle and coverage area.

How can I minimise spray drift?

When spraying outdoors, monitor weather conditions to avoid the risk of pesticide drifting to non-target locations. The best conditions for spraying are when there’s consistent light winds blowing away from sensitive areas, mild temperatures and higher humidity.

Finer droplets are more prone to drift as they have less weight and lose momentum quickly, remaining suspended in the air for a longer time. While this ‘hang time’ makes them ideal for space spraying as they create an insecticide mist that flying insects cannot avoid, it also means they’re more susceptible to being carried away by air currents.

Be sure to only spray when conditions are suitable in order to minimise risks to humans, animals and the environment.

Understanding how different spray components work together helps you to apply the correct amount of pesticide and ensure you get the best results every time.

Find all the spraying equipment, spray guns, nozzles & wands, and sprayer spare parts you need online and in-store at Globe Pest Solutions and if you need personalised advice for your next pest control job, reach out to the experts at your local branch.