Cleaning and Maintenance Tips to Maximise Spray Nozzle Performance

Cleaning and Maintenance of Spray Nozzles

While no spray nozzle will last forever, there are some actions you can take to improve their lifespan. Regular maintenance is essential to ensure optimal performance and prevent the use of damaged nozzles which can cause uneven pesticide application, leading to poor results and costly callbacks. Here’s how to clean and maintain your spray nozzles and recognise when they’re damaged.

What is the best material for spray nozzles?

The nozzle’s material plays a key role in its ability to resist wear from abrasion and chemical exposure.

High quality nozzles are often made of stainless steel or brass as these ensure sharper edges of the outlet hole for a more precise spray pattern. In contrast, plastic nozzles tend to feature more rounded edges of the outlet hole which results in less accurate spray pattern shapes.

What are signs that my spray nozzle is clogged or damaged?

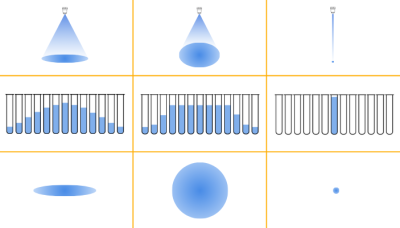

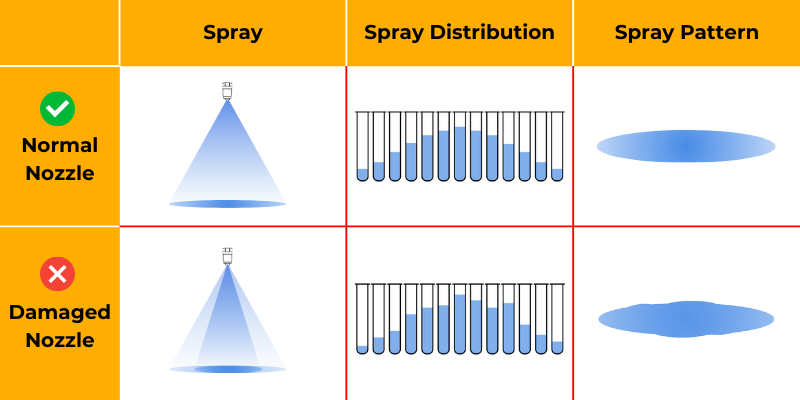

A clogged or damaged nozzle affects both the flow rate and spray pattern, leading to an uneven distribution of product where chemicals are overapplied or underapplied in different areas (see examples below).

To tell if your spray nozzle’s performance has deteriorated, compare its spray pattern and flow rate to a new nozzle of the same size and type, while using the same spray pressure. If the pattern and flow rate are significantly different you should clean the nozzle and if the issue persists, it may be time for a replacement.

Other significant signs of wear include leakage, visible damage or unpredictable performance which indicate that you need to replace the nozzle.

To stay prepared, make sure to always have replacement nozzles on hand.

How often should I clean my spray nozzle?

To keep them functioning properly and to minimise the need for repairs while on the job, you should perform a thorough cleaning of all your spray equipment, including nozzles, at least once a week.

Regularly inspect your equipment for obvious signs of clogging or wear to get ahead of problems before they become serious and always carry spare nozzles and a repair kit so if you do run into trouble on the job you can quickly resolve the issue.

How do I unclog my spray nozzle?

Nozzles are designed with precise orifices so improper cleaning can distort them, affecting the spray pattern, droplet size and flow rate. Similarly if foreign objects or residue clog the tips, your applications will be less accurate and it could cause further damage to the nozzle.

If a tip does clog, only use a soft bristled brush and flush with water or equipment cleaner to clear it. If your nozzles are made with a soft material such as plastic, take extreme care as even a wooden toothpick could damage the orifice. Even brass is a relatively soft metal so avoid using hard metal objects such as wire and pins to unclog a blocked nozzle.

Never blow into the nozzle with your mouth to clear blockages.

What are the best steps to clean my spray nozzle?

- Fill at least 20% of your spray tank with clean water and flush the whole system until all visible residue is removed

- Drain all equipment completely and follow the instructions on the label when disposing of the rinsate

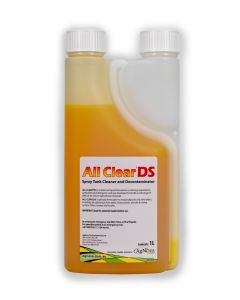

- Fill a bucket with a solution of All Clear DS Tank Cleaner

- Separate the nozzles, strainers, rubber gaskets and tips from the sprayer

- With a soft bristle brush gently scrub the nozzle and other parts with the to remove any remaining residue

- After scrubbing, leave the parts to soak in the cleaning solution as recommended

- Correctly dispose of the solution from the bucket, rinse the nozzles and other equipment parts with clean water and reassemble your equipment or properly store the parts

How can I extend the life of my spray nozzles?

To ensure the longevity of your nozzles and other spray equipment, perform regular visual inspections to spot signs of clogging or wear.

Routinely calibrate your spray system to ensure that it’s applying the correct and expected amount of product.

And finally, when your equipment is not in use, store them in a clean and dry environment to prevent damage from moisture and dust.

Shop all the spray nozzles and sprayer maintenance products that you need for professional pest control online or in-store at Globe Pest Solutions.